Food Processing Automation

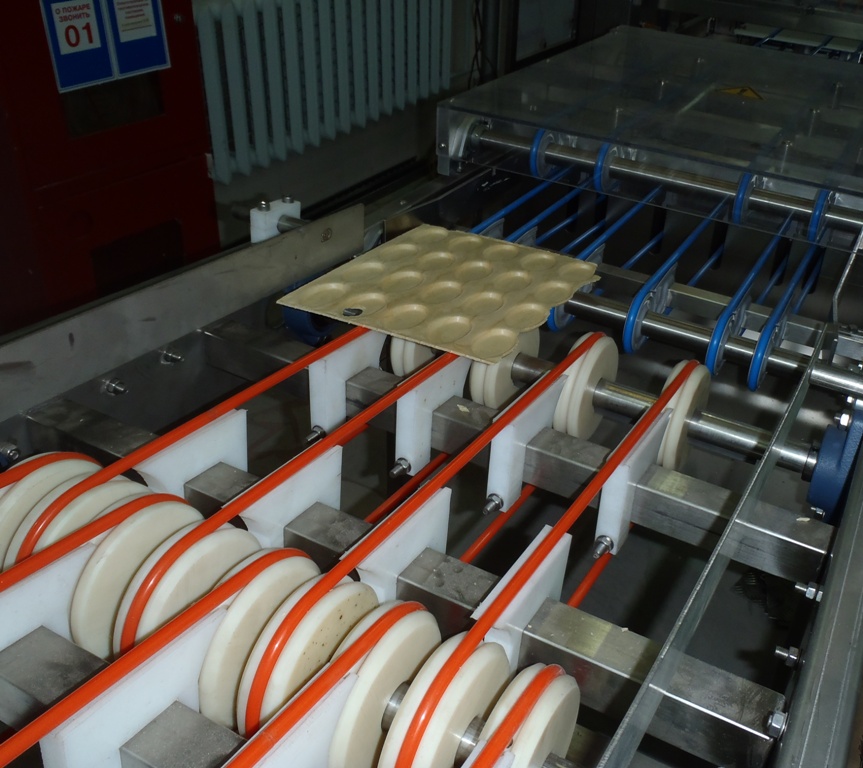

The straps are moved by a special drive shaft that is connected to the motor drive shaft. The straps follow a predetermined path that is determined by a system of rollers and guides with grooves that match the profile of the strap. There are different types of strap profiles, such as wedge-shaped, notched, or round, depending on the type of product that is transported by the conveyor system. Strap conveyors can be extended by adding new modules that are driven by adjacent conveyor sections.

Strap conveyors can also be used for non-standard solutions and integrated into complex conveyor systems. They are widely used in various industries, such as food processing, packaging, freezing, marking, and sealing. Strap conveyors are reliable and simple to maintain. They have a protective feature that prevents the motor from overloading and increases its service life. The service life depends on the operating conditions and is about two years on average.

The only maintenance required is to check the wear and tension of the straps periodically and to lubricate the bearing units.

The other elements, such as shafts, rolls, frames, etc., do not need any maintenance except for occasional inspection of fasteners and sanitary cleaning.

In the case of strap conveyors are possible to increase the conveyor length by adding new modules with a drive from adjacent conveyor sections. Depending on the application strap conveyors can be used for non-standard solutions. Due to their unique characteristics, the strap conveyors are often integrated into the complex conveyor system.

This type of conveyor is widely used in various industries. The most typical examples are:

- Calibration conveyor (vegetables, fruits, etc.)

- Placing boxes on box freezer pallets

- Marking and sealing devices for boxes

- Transporting wafer sheets, fritters, and other confectionery products

- Elevating conveyors for boxes

Strap conveyors are highly reliable due to all elements are simple and do not require special maintenance. Construction features protect the drive motor from overload, thereby increasing its service term. Service term depends on operating conditions, and an average is about two years. During the operation of equipment may need to check for wear and tension of the straps. Tension is provided by rolls, integrated into the structure of the conveyor.

Bearing units are lubricated for all service terms and do not require any maintenance. The rest elements (shafts, rolls, frames, etc.) do not require any maintenance except periodic inspection of fasteners for loosening and sanitary cleaning.

If you are interested in our conveying equipment, you can consult with our experts by phone at + 371 28014638, or by e-mail info@bcsconveyor.com