Food Processing Automation

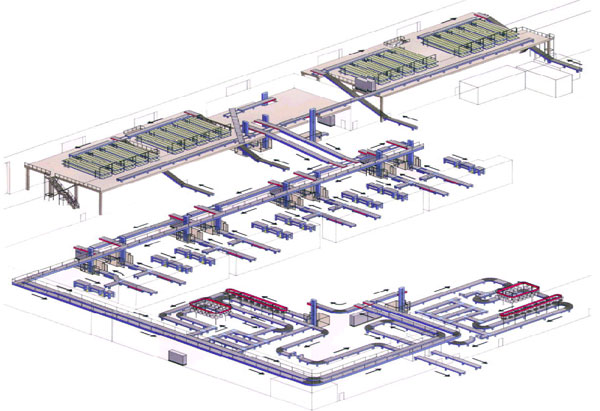

The food industry is currently experiencing rapid growth through the construction of new factories, enhanced production processes, and increased productivity. The optimization of production and logistics processes requires the use of modern automation methods. A well-designed conveyor system can integrate all production stages, minimize operating costs, reduce the number of operators, conserve production and storage space, and improve working conditions.

The food industry is currently experiencing rapid growth through the construction of new factories, enhanced production processes, and increased productivity. The optimization of production and logistics processes requires the use of modern automation methods. A well-designed conveyor system can integrate all production stages, minimize operating costs, reduce the number of operators, conserve production and storage space, and improve working conditions.

The implementation of a conveyor system can be done during the construction of a new enterprise or in an already-established production line. Thus, the creation of an accurate technical specification is a crucial initial step in the design of a conveyor system.

This will involve defining the tasks to be performed by the conveyor system and its expected efficiency.

The technical specification includes a variety of information about the object of automation:

- Layout with the arrangement of the process equipment;

- Characteristics of the transported product;

- Specifications of production lines;

- Required capacity;

- Requirements to structure (material, coating, sanitary conditions);

- Desired equipment control systems, drives, pneumatics, etc.;

- Operation hours

Maximum detailed technical specifications will allow the most correctly designed conveyor systems.

In the composition of the conveyor line, we includes all range of our equipment depending on the characteristics of the required task. Our specialists can design any conveyor system depending on your desire.

If you want to develop a conveyor system, please contact us by phone at + 371 28014638, or by e-mail info@bcsconveyor.com