Food Processing Automation

Conveyor systems are essential for automating the cutting and packaging processes in poultry factories, resulting in a significant increase in economic efficiency. These conveyor systems are utilized in poultry factories of all sizes, ranging from low-capacity factories utilizing manual labor to large poultry factories with high-production lines such as MEYN and STORK.

The primary types of poultry production include chicken and turkey, and the conveyor equipment utilized for these meats is largely identical. However, some distinctions are made based on variations in weight and dimensions between chickens and turkeys.

Conveyors for cutting areas

The capacity of modern automatic cutting lines STORK and MEYN can reach 7,000 heads/hour. With such capacity for further processing are necessary to use conveyor systems. It provides cutting and packaging on the smallest area with the optimal number of staff.

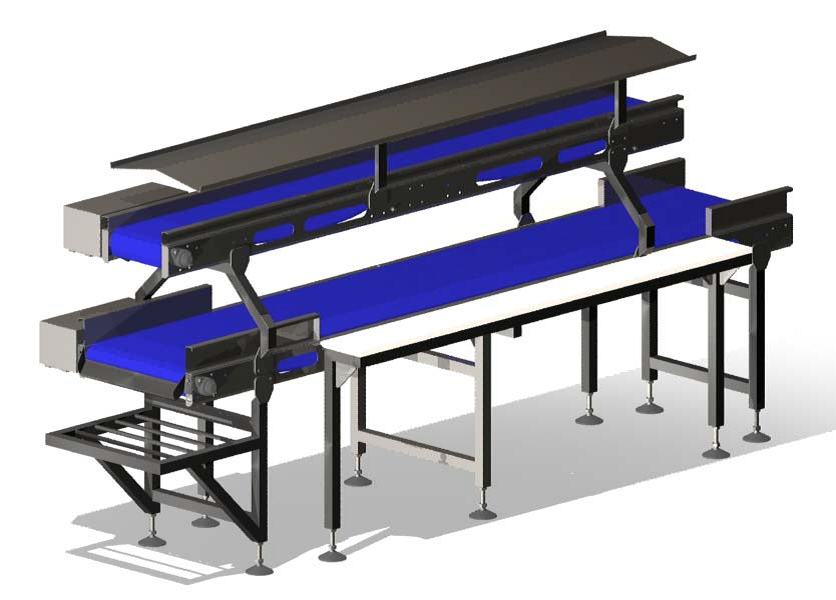

Packing line of by-products

Our packing line is specifically designed for the manual laying of by-products such as heads, hearts, and bowels into trays. The lower layer of the conveyor supplies the by-products from the cutting area to the operators who place them in the trays and verify the weight using integrated scales. The trays are then moved to the second layer and transported by a roller conveyor to the packaging and labeling machine.

To facilitate the operator's task, we have included a stand for empty trays on the third layer of the conveyor. Our side desks are made from high molecular polyethylene and mounted on a metal frame for added durability.

We understand that each department may have different planning needs, and we are happy to offer customized solutions for our customers. Contact us today to discuss how we can help optimize your production line.

Conveyors for poultry parts transportation

Modular belt conveyors are included in the cutting line to perform the transportation of poultry parts from the cutting area to the following stages of processing. At the beginning of the conveyor is set the receiving bin, which excludes product loss.

Difficulties may arise during transporting fillets or skin - need to correctly organize the transition from one conveyor to another.

Cutting conveyors

On the cutting conveyors is made a final cutting: cutting fillets, bones removing, deboning, skin removing, etc. Finished products are supplied further to multilayer conveyors.

Multilayer conveyors

They are used for laying products in the trays and transporting them to the packaging machine. On the first layer are given chicken parts (wings, legs, and fillets, etc.), on the second the operator lay product on the trays, the third layer is used for storage of empty trays.

Conveyors for giving boxes to packaging

The best choice for giving boxes to the packing area is the overhead conveyor. On the empty boxes area, the operator put the empty boxes on special hangers. Then boxes move along a closed way and are supplied to all packaging areas placed in the department. The application of overhead chain conveyors avoids storing boxes near the work desks, thus saving valuable space in the cutting area.

Packing of products

Trays with the products after the packaging machine are fed on an accumulative roller conveyor. The operator fills boxes and puts them on the conveyor feeding to the warehouse. Packing desks can be of different configurations depending on customer requirements.

Products after the shock freezing chamber are usually packed in boxes with an attached polyethylene bag.

Solutions for high capacity

Belt contact freezer for the chicken part

One of our unique products is a conveyor that is utilized to form a thin crust of ice on the bottom surface of cut chicken parts before they are transferred to the spiral conveyor shock freezer. This crucial step is essential in preventing the chicken parts from sticking to the spiral conveyor belt, which could potentially cause an emergency stop due to jamming. Our conveyor system provides a reliable solution to ensure a smooth and efficient production process for our customers in the food industry.

The freezing process takes place on a spiral conveyor equipped with a plastic modular or mesh belt. The conveyor is installed inside a chamber made of heat-insulating sandwich panels. When subjected to shock freezing, small water crystals form which do not cause damage to the cellular structure of the meat, ensuring a high-quality end product. Once the freezing process is complete, the products are packed into boxes and transported to a low-temperature warehouse for storage until they are ready to be shipped.

Shock freezing of poultry meat in boxfreezer

Products are stacked via strap conveyors on metal pallets, which move along the tiers. Moving the pallets with the products is carried out by automated portals.

For best heat transfer boxes should be perforated and have an open tops.

As a rule, before boxfreezer the box buffer is mounted to provide optimal loading products on pallets.

Our company produces both single equipment and complex automated conveyor systems for poultry factories. T

o order, please contact us by phone at + 371 28014638, or by e-mail info@bcsconveyor.com

We guarantee a quick and qualified answer!